- PlastLine Plastics Industry Ltd.

- +36 (20) 916 7670

- plastlinekft@gmail.com

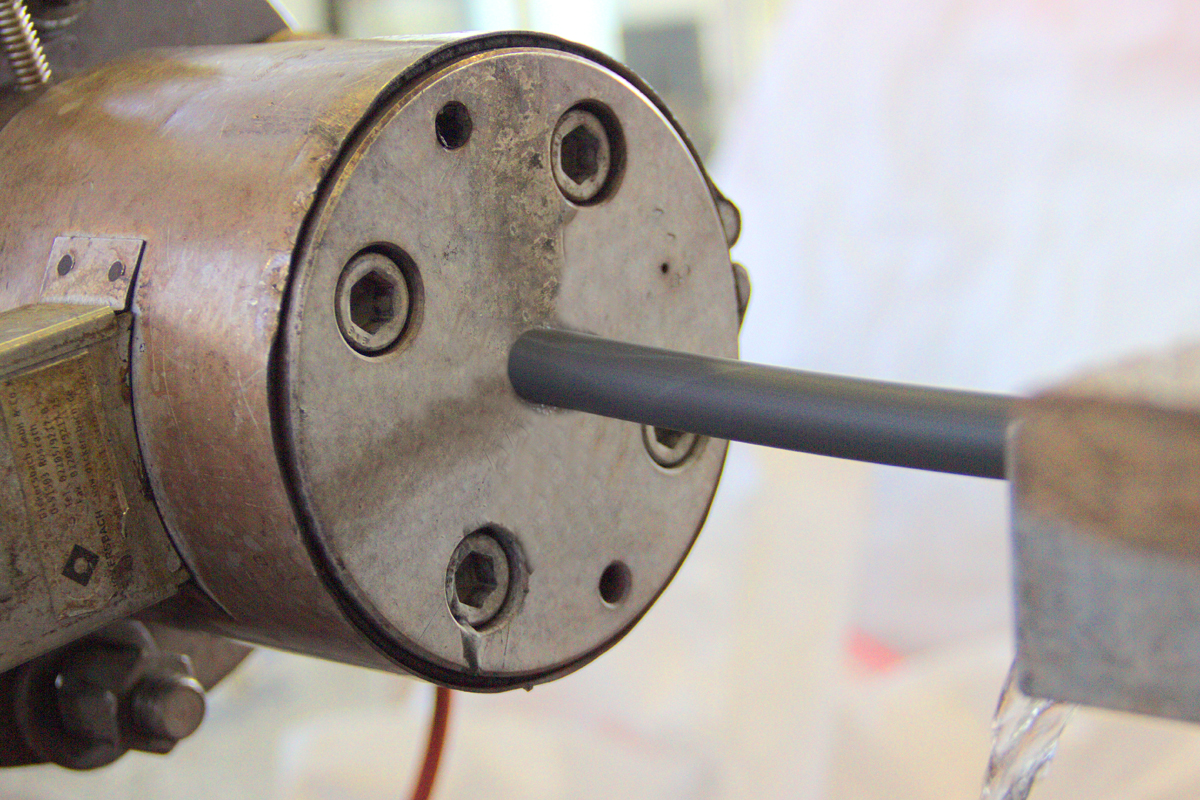

The process technology

In the plastics extrusion process, we feed raw thermoplastic material to the extrusion machine. The rotating screw forces the plastic forward into the barrel that is heated to the desired melt temperature depending on the raw material. After passing through the barrel enters the die. The die is what gives the shape of final product, so that the molten plastic evenly flows through on it and get the final shape, with or without calibration. The product must now be cooled with air or water bath.

Plastic processing

Our technical equipment allows to make tubes, profiles from sizes 1-2 mm to 200 mm x 50 mm. Our twin extruder machine provides the use of the pulverulent raw or recycled materials. During production we use a wide range of plastic materials ( LDPE, HDPE, PP, PS, HIPS, ABS, PC-ABS, SBS, PVC, LPVC, CPVC, (PA, PC, POM, SBS, PUR, TPE, TPU, PMMA, EVA, ect.)

Even in wage work

If you have an extruder tool for your product, but you do not have the option of manufacturing, contact us and we are happy to manufacture your product even from your own raw materials.